Motore passo-passo ibrido Nema 14 (35 mm), bipolare, 4 fili, vite di comando ACME, angolo di passo 1,8°, alte prestazioni.

Motore passo-passo ibrido Nema 14 (35 mm), bipolare, 4 fili, vite di comando ACME, angolo di passo 1,8°, alte prestazioni.

Questo motore passo-passo ibrido da 35 mm è disponibile in tre tipologie: a comando esterno, ad asse passante e ad asse fisso passante. Puoi scegliere in base alle tue esigenze specifiche.

Descrizioni

| Nome del prodotto | Motori passo-passo ibridi da 35 mm |

| Modello | VSM35HSM |

| Tipo | motori passo-passo ibridi |

| Angolo di passo | 1,8° |

| Tensione (V) | 1.4/ 2.9 |

| Corrente (A) | 1.5 |

| Resistenza (Ohm) | 0,95 / 1,9 |

| Induttanza (mH) | 1,5 /2,3 |

| Fili di piombo | 4 |

| Lunghezza del motore (mm) | 35/45 |

| Temperatura ambiente | -20℃ ~ +50℃ |

| Aumento della temperatura | Massimo 80K. |

| Rigidità dielettrica | 1 mA Max. a 500 V, 1 KHz, 1 sec. |

| Resistenza di isolamento | 100 MΩ minimo a 500 Vcc |

Certificazioni

Parametri elettrici:

| Dimensioni del motore | Voltaggio /Fase (V) | Attuale /Fase (UN) | Resistenza /Fase (Ω) | Induttanza /Fase (mH) | Numero di Fili di piombo | Inerzia del rotore (g.cm2) | Peso del motore (G) | Lunghezza motore L (mm) |

| 35 | 1.4 | 1.5 | 0,95 | 1.4 | 4 | 20 | 190 | 34 |

| 35 | 2.9 | 1.5 | 1.9 | 3.2 | 4 | 30 | 230 | 47 |

Specifiche e parametri prestazionali della vite madre

| Diametro (mm) | Guida (mm) | Fare un passo (mm) | Spegnimento forza autobloccante (N) |

| 6.35 | 1.27 | 0,00635 | 150 |

| 6.35 | 3.175 | 0,015875 | 40 |

| 6.35 | 6.35 | 0,03175 | 15 |

| 6.35 | 12.7 | 0,0635 | 3 |

| 6.35 | 25.4 | 0,127 | 0 |

Nota: per ulteriori specifiche sulle viti madri, contattateci.

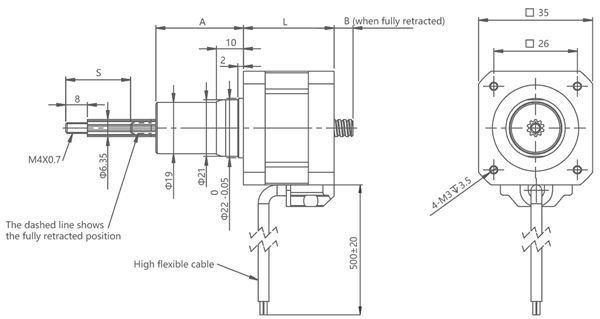

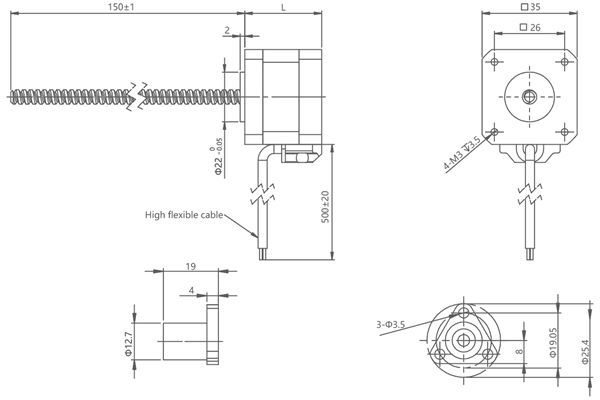

Disegno schematico del motore prigioniero standard dei motori passo-passo ibridi da 35 mm

Note:

La lavorazione personalizzata è fattibile all'estremità della vite di comando

| Colpo S (mm) | Dimensione A (mm) | Dimensione B (mm) | |

| L = 34 | L = 47 | ||

| 12.7 | 20.6 | 8.4 | 0 |

| 19.1 | 27 | 14.8 | 0,8 |

| 25.4 | 33.3 | 21.1 | 7.1 |

| 31.8 | 39.7 | 27.5 | 13.5 |

| 38.1 | 46 | 33.8 | 19.8 |

| 50,8 | 58.7 | 46.5 | 32,5 |

| 63,5 | 71.4 | 59.2 | 45.2 |

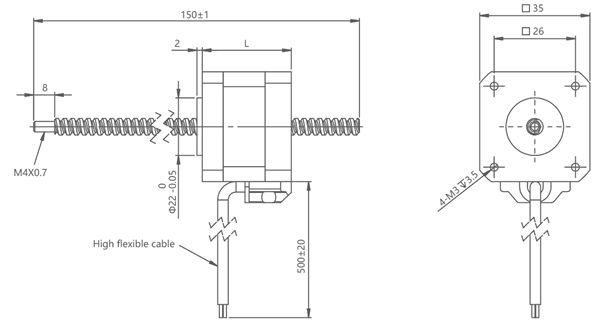

Disegno schematico del motore passo-passo ibrido standard da 35 mm con fissaggio passante

Note:

La lunghezza della vite di comando può essere personalizzata

La lavorazione personalizzata è fattibile all'estremità della vite di comando

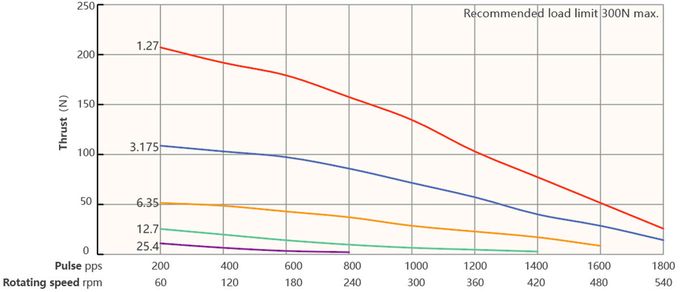

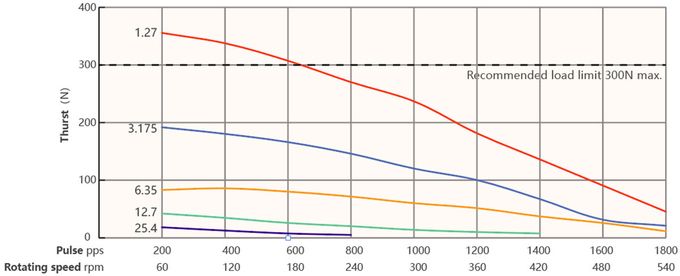

Curva di velocità e spinta:

Motore serie 35 da 34 mm con trasmissione Chopper bipolare

Frequenza di impulso di corrente al 100% e curva di spinta (vite conduttrice Φ6,35 mm)

Motore serie 35 da 47 mm con trasmissione chopper bipolare

Frequenza di impulso di corrente al 100% e curva di spinta (vite conduttrice Φ6,35 mm)

| Piombo (mm) | Velocità lineare (mm/s) | ||||||||

| 1.27 | 1.27 | 2.54 | 3.81 | 5.08 | 6.35 | 7.62 | 8,89 | 10.16 | 11.43 |

| 3.175 | 3.175 | 6.35 | 9.525 | 12.7 | 15.875 | 19.05 | 22.225 | 25.4 | 28.575 |

| 6.35 | 6.35 | 12.7 | 19.05 | 25.4 | 31,75 | 38.1 | 44.45 | 50,8 | 57.15 |

| 12.7 | 12.7 | 25.4 | 38.1 | 50,8 | 63,5 | 76.2 | 88,9 | 101.6 | 114.3 |

| 25.4 | 25.4 | 50,8 | 76.2 | 101.6 | 127 | 152,4 | 177,8 | 203.2 | 228,6 |

Condizioni di prova:

Azionamento chopper, senza rampa, mezzo micro-stepping, tensione di azionamento 40 V

Campi di applicazione

Automazione industriale:I motori passo-passo ibridi da 35 mm trovano ampio impiego nelle applicazioni di automazione industriale. Sono impiegati in vari macchinari e attrezzature, come macchine CNC, robot pick-and-place, sistemi di trasporto e linee di assemblaggio automatizzate. Questi motori offrono posizionamento preciso, elevata coppia in uscita e prestazioni affidabili, rendendoli adatti ad ambienti industriali esigenti.

Robotica:La robotica è un campo di rilievo in cui i motori passo-passo ibridi da 35 mm sono ampiamente utilizzati. Questi motori sono comunemente impiegati nelle articolazioni di bracci robotici e manipolatori, offrendo un controllo preciso sui movimenti del robot. Offrono un'eccellente ripetibilità e precisione di posizionamento, consentendo ai robot di svolgere compiti complessi in ambito industriale, medico e di ricerca.

Macchinari tessili:Nell'industria tessile, i motori passo-passo ibridi da 35 mm vengono utilizzati in vari macchinari tessili, come macchine per maglieria, macchine da ricamo e attrezzature per il taglio dei tessuti. Questi motori forniscono un controllo preciso del movimento degli aghi, dei meccanismi di alimentazione del tessuto e degli utensili da taglio, garantendo una produzione tessile accurata e di alta qualità.

Macchine per imballaggio:Le macchine per il confezionamento richiedono movimenti precisi e sincronizzati per attività come il riempimento, la sigillatura, l'etichettatura e il confezionamento. I motori passo-passo ibridi da 35 mm sono comunemente impiegati in queste macchine grazie alla loro capacità di garantire un posizionamento preciso, una coppia elevata e un controllo fluido del movimento. Consentono operazioni di confezionamento efficienti e affidabili in settori come quello alimentare e delle bevande, farmaceutico e dei beni di consumo.

Automazione di laboratorio:I motori passo-passo ibridi da 35 mm trovano applicazione nei sistemi di automazione di laboratorio, inclusi robot per la manipolazione di liquidi, apparecchiature per la preparazione dei campioni e strumenti diagnostici. Questi motori garantiscono un posizionamento preciso e ripetibile per il pipettaggio, la manipolazione dei campioni e altre attività di laboratorio, facilitando l'automazione e migliorando la produttività.

Elettronica di consumo:Motori passo-passo ibridi di queste dimensioni sono utilizzati anche nei dispositivi elettronici di consumo. Sono utilizzati in dispositivi come stampanti 3D, gimbal per fotocamere, sistemi di domotica e robotica di consumo. Questi motori consentono un controllo preciso dei movimenti e delle funzioni di questi dispositivi, migliorandone le prestazioni e l'esperienza utente.

Vantaggio

Alta precisione:Questi motori offrono un controllo di posizione ad alta precisione. In genere, hanno un'elevata risoluzione angolare, consentendo passi minuscoli e un posizionamento preciso. Questo li rende adatti ad applicazioni che richiedono un controllo di movimento di precisione, come sistemi di posizionamento, strumenti di precisione, ecc.

Buone prestazioni a bassa velocità:I motori passo-passo ibridi da 35 mm offrono ottime prestazioni a basse velocità. Sono in grado di fornire un'elevata coppia in uscita, rendendoli adatti ad applicazioni che richiedono un'elevata coppia di spunto o che operano a basse velocità. Questo li rende adatti a scenari che richiedono un controllo preciso e un movimento lento, come apparecchiature medicali, strumenti di precisione e altro ancora.

Controllo semplice dell'azionamento:Questi motori hanno un controllo di azionamento relativamente semplice. Solitamente sono controllati tramite controllo ad anello aperto, il che riduce la complessità e i costi del sistema. Circuiti di azionamento adeguati possono garantire un controllo accurato della posizione e della velocità dei motori passo-passo.

Affidabilità e durata:I motori passo-passo ibridi da 35 mm offrono elevata affidabilità e durata. Sono generalmente realizzati con design e materiali magnetici di alta qualità che mantengono prestazioni stabili per lunghi periodi di funzionamento e frequenti avvii e arresti. Questo li rende adatti ad applicazioni che richiedono lunghi tempi di funzionamento e un'elevata affidabilità.

Risposta rapida e prestazioni dinamiche:Questi motori hanno tempi di risposta rapidi e buone prestazioni dinamiche. Sono in grado di ottenere cambi di posizione precisi in tempi brevi e possono accelerare e arrestarsi rapidamente. Questo li rende adatti ad applicazioni che richiedono tempi di risposta rapidi e prestazioni dinamiche elevate, come robotica, apparecchiature di automazione, ecc.

Ampia gamma di campi di applicazione:I motori passo-passo ibridi da 35 mm sono utilizzati in un'ampia gamma di settori e applicazioni. Sono adatti per l'automazione industriale, la robotica, le apparecchiature medicali, le apparecchiature tessili, le macchine per l'imballaggio, l'automazione di laboratorio e molti altri settori. I vantaggi di questi motori li rendono ideali per numerosi scenari applicativi.

Requisiti per la selezione del motore:

►Direzione di movimento/montaggio

►Requisiti di carico

►Requisiti per l'ictus

►Requisiti di lavorazione finale

►Requisiti di precisione

►Requisiti di feedback dell'encoder

►Requisiti di regolazione manuale

►Requisiti ambientali

Officina di produzione

.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)